Stone Slabs & Countertops

Premium Natural & Artificial Stone | 15+ Years Expertise | Global Exporter

A trusted leader in research, development, and production of high-quality artificial stone and natural stone slabs in South China with more than 15 Year expertise

Stone Slabs & Countertops

Premium Natural & Artificial Stone | 15+ Years Expertise | Global Exporter

A trusted leader in research, development, and production of high-quality artificial stone and natural stone slabs in South China with more than 15 Year expertise

Large-Scale Production Excellence

Harness Cutting-Edge Equipment & Technicque

Premium Solid Surfaces for 30+ Global Markets

From Value-Focused to Luxury Stone Slabs

Delivering premium solid surface materials to global markets more than 30 countries.

Products are ranging from economical types to high end luxury stone slabs.

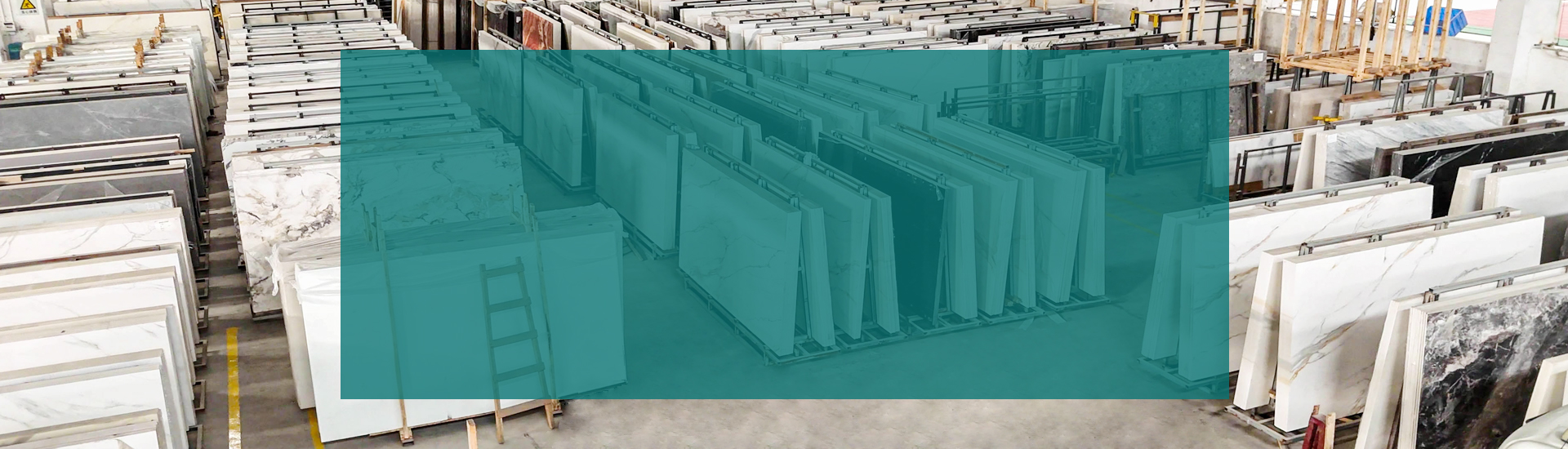

One Million+ Sq.Ft. of Premium Stone Slabs in Stock Ready to Ship – Your Order, Your Choice

Choose from 100,000+ sqm of high-quality standard-design slabs for immediate delivery. Awarded by international stone slabs supplying unites worldwide.

Custom Countertops: Precision-Crafted to Your Designs

Our skilled craftsmen and engineers can bring any countertop vision to life - no design challenge is too complex for our team." Strive the be an excellent partner of cabinets manufacturers.

-

Profile

G-Stone

G-Stone is a leading artificial stone brand specializing in the production of solid surface slabs and advanced surface processing solutions.

Established in 2009, we relocated our headquarters to Guangzhou in 2016 to better serve our expanding customer base. Today, we operate three state-of-the-art production facilities in Yunfu, Foshan, and Dongguan, each dedicated to manufacturing quartz stone slabs, engineered granite slabs, and sintered stone slabs. Collectively, these facilities produce over 1 million square meters of premium materials annually, solidifying our position as a key player in the artificial stone industry.

-

What We Produce

Product

Premium Quality, Affordable Solutions for Global Markets

Supplying distributors, cabinet manufacturers, contractors, property owners, and developers worldwide:

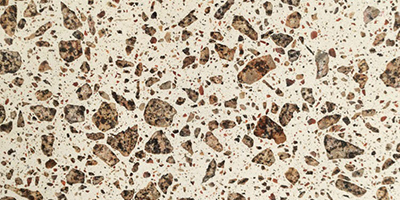

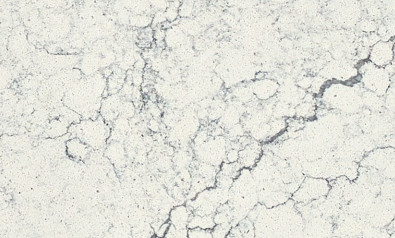

- Quartz Stone: Timeless classics and modern designs, including nanolized solid surfaces and non-silica quartz slabs.

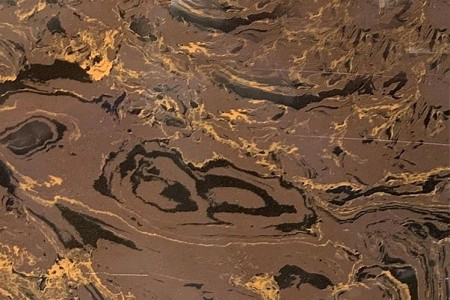

- Engineered Granite: Cost-effective yet stylish countertops and flooring with a variety of textures.

- Sintered Stone: Innovative designs and advanced equipment for diverse market needs.

-

Be Our Partner

Service

Exceptional Service Comparable to Your Own Factory – Satisfaction Guaranteed

- Custom Slab Pattern Design & Production: We specialize in creating unique slab patterns tailored to your needs or original natural stone sample, ensuring your products stand out in the market with unmatched originality.

- Massive Inventory Capacity: With over 100,000 square meters of artificial stone slabs in stock for regular models, we guarantee fast and efficient delivery to meet your deadlines.

- Advanced Countertop Processing: Our state-of-the-art production capabilities allow us to bring your most intricate countertop designs to life, precisely as you envision them.

G-Stone: Solve Your Stone Slabs & Countertops Frustrations

Designers | Cabinets Fabricators | Installers | Homeowners | Contractors & Builders | Real Estate Developers | Wholesalers

Stop battling with consistency, waste, surprises, cost, or care?

We see your granite, marble, quartz challenges daily. Explore the real headaches here and let`s solve them.

● Material Consistency: Variations in color/veining can disrupt design uniformity in cabinet projects.

● Workability: Hard stones (e.g., granite) increase tool wear; soft stones (e.g., marble) risk chipping during fabrication.

● Supply Chain Reliability: Delays in slab deliveries bottleneck production schedules.

● Cost Negotiation: Bulk discounts are critical for competitive pricing in high-volume orders.

● Schedule Risks: Late stone deliveries delay entire construction phases, incurring penalties.

● On-Site Adaptability: Slab dimensions/thickness must match blueprints to avoid re-cutting or returns.

● Labor Challenges: Heavy slabs require specialized equipment/crew, increasing labor costs.

● Durability Guarantees: Clients demand stain- and scratch-resistant materials to avoid post-installation complaints.

● Bulk Material Sourcing: Need cost-effective, high-volume suppliers for subdivision or multi-unit projects.

● Standardization: Consistent color/finish across all units (e.g., condo kitchens) is non-negotiable.

● Speed of Installation: Pre-cut or modular stone solutions speed up construction timelines.

● Warranty & Liability: Prefer suppliers who cover damage during installation or defects.

● Code Compliance: Materials must meet local regulations (e.g., fire ratings for high-rises).

● Decision Overwhelm: Confusion over stone types (e.g., quartz vs. marble) and long-term care.

● Budget Surprises: Hidden costs (e.g., seam placement, edge detailing) inflate quotes.

● Maintenance Anxiety: Fear of etching (marble) or heat damage (quartz) leads to analysis paralysis.

● Trust Gaps: Vetting suppliers for reliability (e.g., template-to-installation accuracy).

● Economies of Scale: Negotiating slab pricing for 100+ units impacts profit margins.

● Aesthetic Uniformity: Batch inconsistencies (e.g., quartz lots) risk buyer complaints in luxury projects.

● Turnkey Solutions: Prefer suppliers who handle fabrication/installation to streamline operations.

● Future-Proofing: High-traffic areas demand ultra-durable materials (e.g., sintered stone).

● Cash Flow Pressure: Slow-moving inventory (e.g., exotic marbles) ties up capital.

● Global Sourcing Risks: Geopolitical issues or shipping delays disrupt supply (e.g., Italian quarries).

● Trend Adaptation: Must pivot stock (e.g., rising demand for porcelain slabs) without overstocking.

● Damage Liability: Broken slabs in transit result in profit loss and client disputes.

● Vision Execution: Limited by slab sizes (e.g., unable to book-match small-format marble).

● Sample Logistics: Physical samples are heavy/costly to ship; digital tools may lack accuracy.

● Customization Delays: Complex cuts (e.g., angled islands) require longer lead times.

● Sustainability Demands: Clients seek recycled content or low-VOC adhesives for LEED certification.

Whether you’re a property owner seeking premium artificial stone materials, a real estate developer requiring bulk supply, or a designer looking for the perfect finish, we cater to your specific needs. Our solutions are equally valued by cabinet manufacturers crafting fine furniture, project contractors managing tight timelines,and wholesalers needing reliable stone slab inventory.

“Your Challenges, Our Commitment” We understand your pain points and the precision your project demands. Count on our full cooperation to deliver flawless execution – because your perfect finish is our mission.

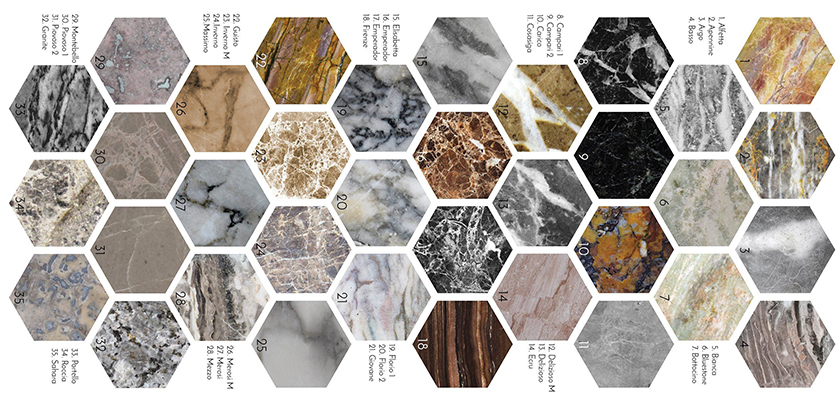

Different Stone Slabs for Buyer`s Guide

We currently manufacture and supply the following types of stone slabs, which covers most the artificial stone materials used for countertops of interior and outdoor surface covering. In case you cannot find what you are looking for, don`t hesitate to send us a photo of your stone. More than half of our partners have started cooperation with us with a simple photo of stone texture.

Microcrystalline stone

Free Silica Quartz Stone

Natural Marble Slabs

Natural Granite Slabs

Sized Porcelain Slabs

The Countertops for Buyer`s Guide

Source premium granite, marble, & quartz slabs direct from us. Then we can further expertly fabricate them into custom countertops, vanities, cladding, and bespoke architectural elements – precisely cut, finished, and installed to your project’s demanding specifications. Streamline your supply chain with one reliable partner for raw stone & finished products.

Stock for Sale

Skip the wait and accelerate your projects! Our extensive inventory of readily available natural stone slabs and artificial stone slabs eliminates long lead times. Partners gain immediate access to a vast selection, enabling faster order fulfillment, quicker installations, and seamless project flow. Leverage our stock for reliable timelines and enhanced responsiveness – your convenience is our priority. Partner with efficiency.

Stock For Sale

June 2025

● 10 USD Per/sqm Starting Price

● 100+ Models For Your Choice

● 100,000 Sqf Warehouse As Stock Area

●1,000,000 Sqf Stone Slabs Ready To Ship

Your Project Vision, Our Stone Solid Promise & Expertise

From First Photo to Final Installation!

Why Clients Love Working With Us for Stones

-

One Photo of Slab from You to Start – No complicated service process

-

End-to-End Management – We handle for you to door with all details

-

Transparent Updates – Know your project status

-

Stress-Free Results – Perfect countertops, guaranteed

Simply send us a photo of your stone or countertop project with sizes, and we’ll handle the rest: material selection, custom solutions, precise quoting, CAD drawings, and flawless delivery – all with white-glove service.

What Makes G-Stone Different From Others ?

We take pride in exceptional stone products and meticulous service. Our commitment to quality craftsmanship and durable materials shines through in every project. Don’t just take our word for it – explore the gallery below showcasing real installations. See firsthand how we transform spaces with premium stone and reliable solutions.

Stock Selection / Ready-to-Ship Slabs

Immediate availability from our inventory, reducing lead times for urgent projects (on-site photo)

Custom-Cut Slabs

Precision-cut to your specified dimensions, ensuring minimal material waste and perfectly fit. (stone parts are protected on red carpet)

Project-Specific Fabrication

Tailored solutions for architectural or large-scale projects, from unique finishes to complex shapes (on-site photo)

Luxury Stone Customization

Exclusive access to high-end, rare stone varieties, crafted to bespoke design requirements.

Domestic and Abroad Project Parnters

With dozens brands of world-famous developers, hotels, contractors, G-Stone treat seriously with each product that are delivered.

Discover why the dimensions of your quartz slab reveal crucial differences in quality, durability, and long-term performance. Learn how manufacturing processes differ between large-format slabs and smaller strips.

Real money talks, and when it comes to luxury interior design in Malaysia’s high-end villas and hotels, the choice of materials must balance aesthetics, durability, and cost-effectiveness. While natural stones like marble slab and granite have traditionally been popular, quartz stone slab has emerged as the superior choice for discerning

Many ask: “Is custom stone a practical choice, or just a luxury for the elite?“

To Meet Your Need of Stone Easier

Whether you need premium stone solutions or want to explore possibilities, contact us today. We commit to excellence in every slab and service, ensuring your project delivers lasting beauty, value, and a seamless partnership. Your vision, perfected in stone.